UV ink fails to cure in the correct place on the press.

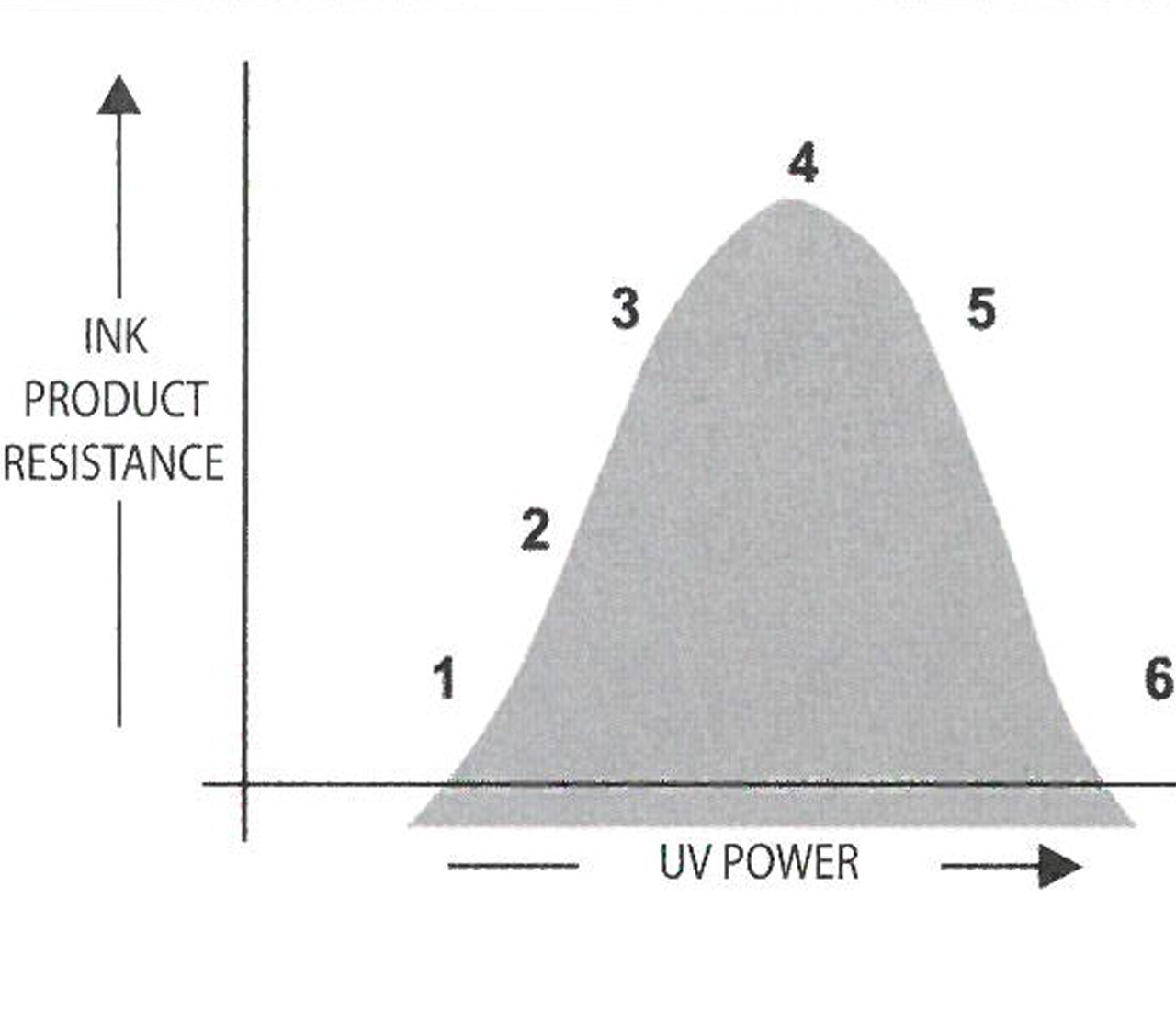

As UV inks and coatings are exposed to ultraviolet light:

- Little or no exposure – ink remains liquid;

- Polimerizzazione parziale (di solito si tratta solo della superficie)

- Partial curing (usually surface only) with possible ‘skinning’ and generally poor adhesion to the substrate;

- Tacky surface, common to under curing;

- ‘Correctly cured’ with no tack, low odour, flexible and with good adhesion;

- Increased surface hardness that can become brittle with poor over printability;

- Primary ink surface not receptive to secondary inks resulting in poor adhesion and low flexibility with flexo and letterpress processes.

Causes:

– Direct exposure to sunlight or to general lighting sources;

– Smell from ink;

– Ink is reticulating on top of the first colour (often screen white);

– Cured ink has poor adhesion to the film substrate;

– Lamp problems:

- Low lamp power setting;

- Weak exposure bulbs;

- Dirty lamp reflectors;

- Incorrect lamp focus.

Solutions:

– Eliminate direct exposure to sunlight. Use UV filter covers on light above the press;

– Ink not sufficiently cured. Turn up UV lamp power to a minimum of 100 W/cm and check the lamp and reflectors are clean. Reduce press speed to increase UV lamp dwell time;

– Over curing the white ink. Turn the lamp power down to a point where there is no surface tack but good secondary ink reception;

– Excessive curing of the ink causing shrinkage of the ink film. Turn the power of the lamps down to a minimum and also check the dyne level of the film.

– Lamp Solutions:

- Increase lamp power setting;

- Replace exposure bulbs;

- Clean lamps reflectors;

- Adjust focus to optimal distance.