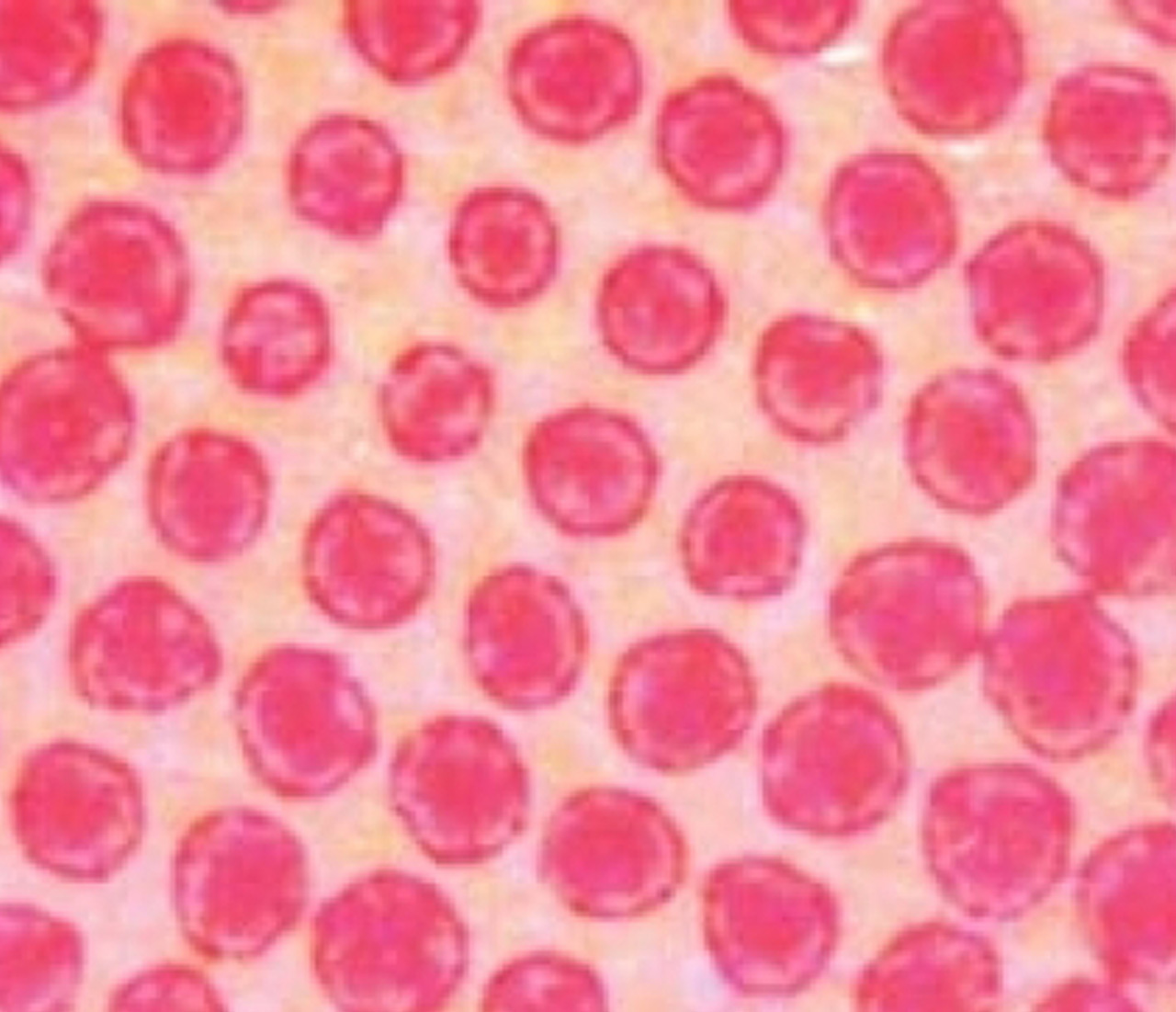

An excessive increase in the size of a halftone dot from film to the printed image.

Causes:

-Excessive ink volume;

-Excessive plate thickness or plate swelling;

-Wrong tape or trapped air;

-Excessive pressure settings;

-Poor ink metering application;

-Damaged or worn press parts;

-Dirt on impression and/or plate cylinders;

-Viscosity too low.

Solutions:

– Reduce anilox volume to a minimum while maintaining colour balance;

– Use thinner plates;

– Check for trapped solvents in the finished plate;

– Change to a cushion mounting tape;

– Check for bubbles under the mounting tape, burst and remount plate;

– Reduce pressure settings to a minimum;

– Use a doctor blade metering system;

– Check and replace damaged or worn gears, bearings or cylinders;

– Clean impression and/or plate cylinders;

-Check and maintain ink viscosity.