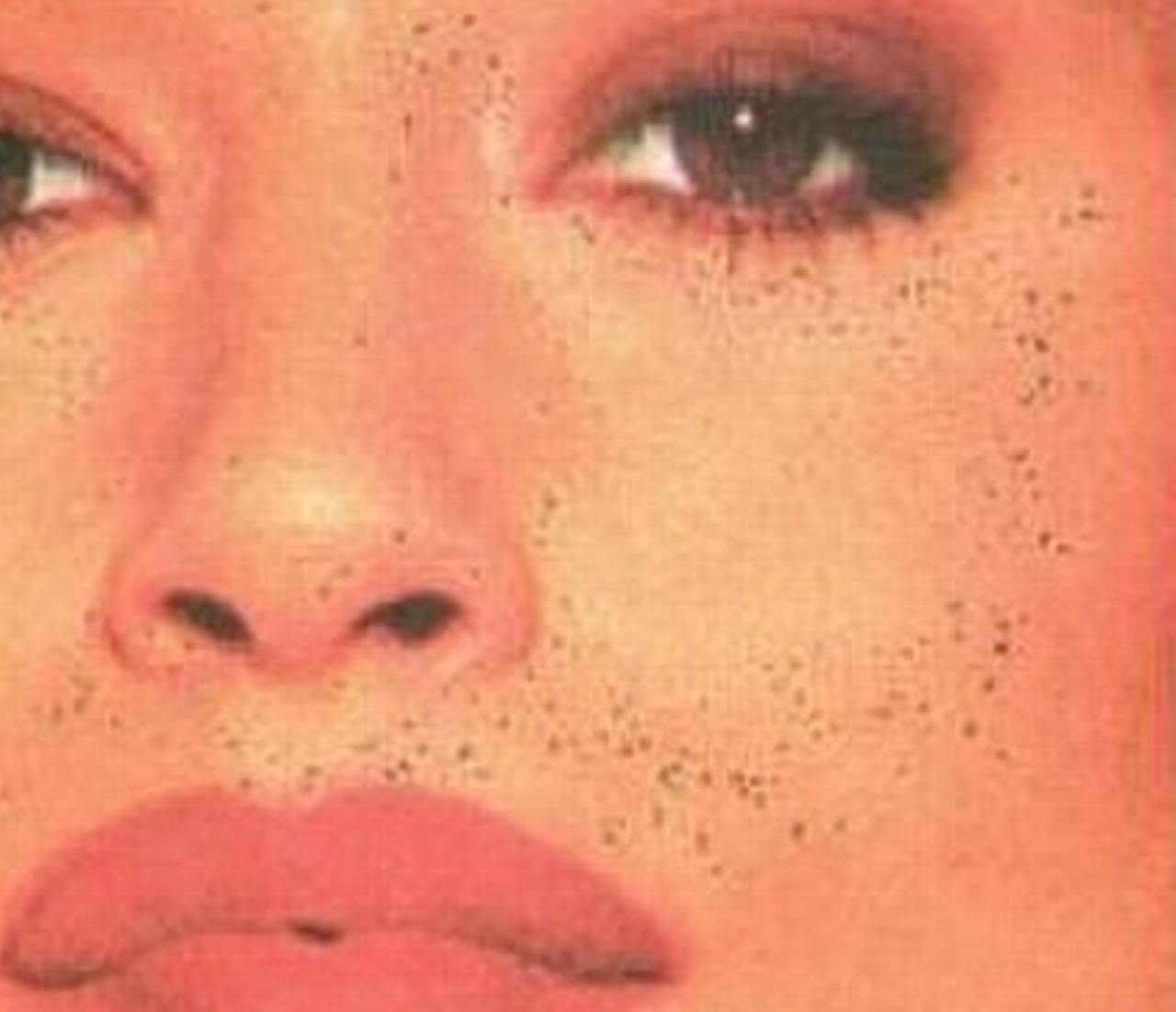

Excessive ink transfer to substrate. Excess colour strength.

Causes:

– Ink viscosity too high or too low with dot gain;

– Colour concentration too high;

– Ink film too thick;

– Contamination from previous colours;

– Nip pressure between rubber roll and anilox roll;

-Wrong anilox roll.

Solutions:

– Check and maintain correct ink viscosity, use a kiss impression only;

– Add extender to ink, reduce ink film thickness;

– Reduce ink thickness by lowering ink viscosity, increasing ink metering effectiveness, decreasing machine speed or anilox volume.Check doctor blade is parallel with a minimum pressure setting;

– Thoroughly clean press station between colour changes and replace ink;

– Set nip pressure to minimum setting or select fountain roll with a higher durometer;

– Change anilox roll specification to a lower cell volume.